Optimizing Silage Corn Chopping: Best Practices

Silage Corn is a valuable feed source for livestock farmers, providing essential nutrients for optimal animal health and performance. Optimizing the corn-chopping process is crucial to ensure the highest quality of hay. This article explores the best practices for Optimizing corn silage to maximize feed quality and animal productivity.

Table of Contents

The Importance of Silage Corn Chopping

Proper chopping of silage corn is essential for breaking down plant materials into digestible forms and promoting efficient fermentation. Chopping affects particle size, fibred digestibility, and overall nutrient availability.

Factors Affecting Silage Quality

Several factors can influence the quality of corn silage.

Moisture Content

Water content in the forage is crucial for producing high-quality hay. It must be at the appropriate level to ensure proper fermentation and prevent spoilage. If the forage is too dry, it will not ferment effectively. Conversely, excessive moisture can lead to poor fermentation and mold growth.

Kernel Processing

In the case of silage corn, breaking or crushing the kernels during chopping is beneficial. This process enhances silage quality by releasing the starch inside the kernels, making it easier for animals to digest.

Chop Length

The length of the chopped forage is an important consideration. It should be cut into pieces of the appropriate size to ensure proper compaction and minimize the presence of air. This facilitates the fermentation process and preserves the nutrient content of the hay. Typically, forage pieces around 0.5 to 1.0 inches (1.3 to 2.5 cm) long are recommended.

Packing Density

Achieving a tightly packed forage is vital for optimal silage quality. Adequate compaction eliminates air and creates a favourable environment for beneficial bacteria growth. This aids in the fermentation process and helps retain the nutrient value of the hay. If the forage is not packed tightly enough, it may spoil and experience nutrient loss.

Benefits of Optimizing Silage Corn Chopping

More Nutrients for Animals:

Cutting the corn to the right length makes it easier for animals to digest and utilize the nutrients in the hay. This improves animal health and performance.

Better Quality Feed:

Overall silage quality improves when we cut the corn to the correct length, control the moisture, and process the kernels properly. It ferments well, resists spoilage, and retains more nutrients for the animals to consume.

Efficient Feed Utilization:

Properly chopping and processing corn helps animals utilize feed more efficiently. They extract more nutrition from their diet, which reduces feed costs and promotes better growth and productivity.

Reduced Feed Waste:

Feed waste is minimized by cutting the corn to the appropriate length and tightly packing it. Animals engage in less sorting of the feed, resulting in decreased waste. This saves money and optimizes hay utilization.

Cost Savings:

We can save costs by monitoring moisture levels and employing suitable equipment. This reduces expenses and ensures the proper functioning of our equipment.

Enhanced Animal Health:

Optimizing silage corn chopping improves animal feed quality. They experience better health, reduced susceptibility to diseases, and increased reproductive success—the entire herd benefits from improved well-being.

Time Efficiency:

Following correct chopping practices enhances work efficiency and saves time. Tasks can be performed more effectively, enabling optimal utilization of time and resources

Troubleshooting Silage Fermentation Issues: Expert Advice

When it comes to troubleshooting silage fermentation issues, several common problems can arise. Here is some expert advice on how to address these issues.

Step 1: Evaluate packing density

- Ensure the silage is packed tightly to remove excess air.

- Use heavy machinery or add additional layers of forage to increase packing density.

- Insufficient packing can lead to poor fermentation.

Step 2: Check moisture levels

- Verify that the forage has the appropriate moisture content for ensiling.

- If the forage is too dry, add water during the ensiling process.

- Consider using a dry matter additive to improve fermentation if it is too wet.

Step 3: Adjust chop length

- Ensure the forage is chopped to an appropriate length for effective fermentation.

- Longer chop lengths can hinder fermentation.

- Make adjustments as necessary to optimize chop length.

Step 4: Assess wilting time

- Check if the forage has been wilted adequately before ensiling.

- Inadequate wilting can result in a higher pH.

- Allow sufficient time for wilting to remove excess moisture.

Step 5: Add fermentation aid

- Consider using a bacterial inoculant or acid-based additive to improve fermentation.

- These additives can help lower pH levels and enhance the fermentation process.

Step 6: Check moisture content again

- Excessive moisture can lead to mold growth and heating.

- Reassess the moisture content of the forage and make adjustments if necessary.

Step 7: Improve compaction

- Ensure proper compaction during the ensiling process.

- Poor compaction can create air pockets that promote mold growth.

- Pack the silage tightly and eliminate any gaps or voids.

Step 8: Use an effective inoculant

- Select a bacterial inoculant with anti-fungal properties to inhibit mold growth.

- A suitable inoculant can help prevent the development of mold during fermentation.

Step 9: Check for air exposure during feed-out

- Offensive odors can indicate aerobic spoilage caused by oxygen exposure.

- Ensure proper sealing of the hay and use oxygen barrier films.

- Inspect the covering for any damage or punctures that may allow air to enter.

Step 10: Monitor feed-out practices

- Avoid excessive exposure to air during feed-out.

- Remove spoiled or heated hay before feeding.

- Proper feed-out management helps maintain palatability.

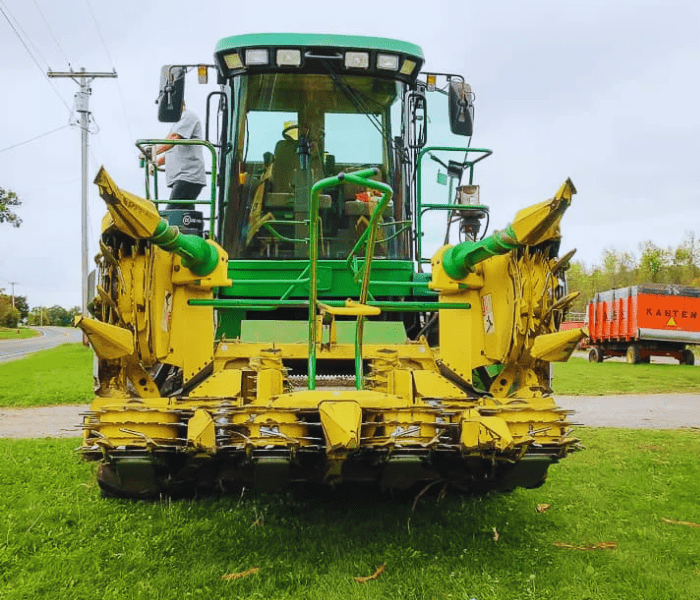

Choosing the Right Machine for Silage Corn Chopping

Match machine capacity to your expected silage corn volume.

Capacity

Determine the amount of silage corn you need to process within a given time frame. Choose a machine with an appropriate capacity to meet your requirements.

Cutting mechanism

Silage corn choppers typically use either drum or disc-cutting mechanisms. Drum choppers are better suited for coarse chopping, while disc choppers provide finer cutting.

Durability and maintenance

Look for a machine with a robust design and high-quality construction. Consider the availability of spare parts and the manufacturer’s reputation for after-sales support. Additionally, choose a machine that is easy to maintain.

Feeding and discharge systems

Evaluate the efficiency and effectiveness of the machine’s feeding and discharge mechanisms. Ensure that the feeding system can handle the volume of silage corn, and the discharge system allows for easy collection and transport of the chopped hay.

Safety features:

Prioritize machines with good safety features, such as guards, emergency stop buttons, and safety sensors. Ensure the machine complies with relevant safety standards and regulations to protect operators and prevent accidents.

Budget

Consider your budget constraints and the long-term cost of ownership. Compare prices, financing options, and the overall value different machines offer.

Manufacturer Support:

Do some research on the company that makes the machine. Check if they have a good reputation, good customer support, and if it’s easy to get parts and services.

Best Practices for Optimizing Silage Corn Chopping

Harvest Timing

Harvesting silage corn at the ideal stage of maturity is vital for maximizing yield and nutrient content. The optimal time for chopping is typically when the corn reaches 30-35% dry matter (DM) content, ensuring proper fermentation and minimizing nutrient losses.

Kernel Processing

Efficient kernel processing enhances starch availability, improving energy utilization by livestock. Adequate kernel processing involves cracking or crushing the kernels to expose the endosperm without excessively damaging the cob.

Chop Length

Determining the optimal chop length is essential for maximizing particle size distribution and fiber digestibility. A shorter chop length improves packing density, reduces sorting, and enhances fermentation. However, excessively short chop lengths may increase power requirements and risk packing density issues.

Adjusting Moisture Content

Proper moisture content is crucial for successful ensiling and fermentation. Adjusting the moisture content to the target range of 60-70% helps ensure anaerobic conditions and inhibit undesirable microbial growth. Testing the moisture content using reliable methods such as the microwave or Koster tester is advisable.

Packing and Storage

Thorough packing and proper storage are vital for minimizing air infiltration and preserving silage quality. Adequate packing density reduces oxygen availability, preventing spoilage and maintaining feed value. Pay attention to filling rates, layer thickness, and covering silage to create an effective oxygen barrier.

Maximizing Efficiency: Silage Corn Harvester Tips

- Harvest Timing: Monitor the crop closely and harvest when it reaches the appropriate maturity stage for the desired moisture content.

- Moisture Testing: Use a reliable moisture meter to measure the moisture levels of the harvested crop. Take multiple samples across the field to ensure accurate readings.

- Determine Target Moisture Content: Know the target moisture range for the specific forage type being harvested. This information helps guide adjustments and decisions during the process.

Monitoring and Evaluating Silage Quality

Fermentation Checking the Silage

Checking the fermentation process helps catch problems early. We look at things like pH levels, temperature, and signs of spoilage, like mold or bad smells. This helps us see if the silage is fermenting well and if there are any issues.

Feeding the Silage

Feeding the silage the right way is important. We must avoid letting air in when we remove it from the silo. Keeping the silage face clean and managing how much we take out at once helps keep it fresh. We must also cover any exposed silage quickly to keep it good for feeding.

We are checking the Nutrients.

We need to regularly check the nutrients in the silage corn. This helps us know how much dry matter, protein, fiber, and energy it has. With this information, we can adjust the animal’s diet to ensure they get the right nutrition and do well.

Taking Care of Equipment and Staying Safe

Keeping the chopping equipment in good shape is important. We need to check and fix things like blades and shear bars regularly. This helps prevent problems and makes sure everything works well. We must also follow safety rules and wear protective gear while chopping the silage.

Conclusion

Optimizing Silage corn Chopping best it can be is important for feeding animals and helping them grow strong. There are some things farmers can do to make the hay better. They must harvest the corn at the right time, ensure it’s not too wet or too dry, and process the kernels properly. Packing it tightly and caring for it when storing it is also important. Farmers should monitor it, feed it correctly, and care for their equipment. The animals get the best food, grow well, and stay healthy when they do all these things.

Frequently Asked Questions (FAQ’s)

How can I determine the right moisture content for corn silage?

Testing the moisture content using reliable methods such as a microwave or a tester is advisable. The target range for moisture content is typically 60-70%.

What is the ideal chop length for corn silage?

The ideal chop length for silage corn varies. Still, a shorter chop length improves packing density, reduces sorting, and enhances fermentation. However, excessively short chop lengths may increase power requirements and risk packing density issues.

Why is kernel processing important in corn silage chopping?

Efficient kernel processing enhances starch availability, improving energy utilization by livestock. It involves cracking or crushing the kernels to expose the endosperm without excessively damaging the cob.

How often should I analyze the nutrient composition of corn silage?

Regularly analyzing the nutrient composition of corn silage is recommended, especially during significant changes in growing conditions or forage sources. This allows for informed nutritional adjustments and ensures optimal animal diets.

What are some safety precautions to consider during corn silage chopping?

When chopping silage corn, following safety protocols and wearing appropriate personal protective equipment (PPE) is crucial. Regular equipment maintenance, inspection of critical components, and adherence to safety guidelines help prevent accidents and injuries during the chopping process.

Related Articles

Want to purchase top quality corn silage. Visit our Agricomplex website. Easy and Helpful information just for you!

People Also Asked

What are the best practices for corn silage chopping?

We have some important rules to follow when we chop corn for silage. We cut the corn into tiny pieces, like little bits, so it’s easy for animals to eat and their bodies can use it well. We also ensure all the pieces are the same size, so the hay is always yummy and good for the animals.

What equipment is necessary for efficient corn silage chopping?

Efficient corn silage chopping requires a forage harvester or chopper, a tractor with a corn header attachment, and a wagon or silage truck for transportation. Regular equipment maintenance is essential for optimal performance and quality silage production.

How can I optimize corn silage chopping?

- Harvest at the right stage for optimal nutrient content.

- Adjust the chop length for proper compaction.

- Process the kernels for better digestion.

- Maintain equipment for efficient operation.

- Control moisture content to prevent spoilage.

How does the chop length affect corn silage quality?

Chop length affects corn silage quality. Smaller chop lengths promote better compaction and fermentation, preserving nutrients. They also improve animal digestibility, enhancing feed efficiency and overall hay quality.

Are there any specific techniques to reduce spoilage during corn silage chopping?

- Adjust moisture content within the optimal range.

- Achieve a high packing density by compacting the forage tightly.

- Cover and seal the hay to create an anaerobic environment.